Electronics

The rapidly evolving consumer electronic market has created a number of challenges and opportunities for electronics manufacturers. The demand for smart electronics devices has made electronic manufacturing complex enough that expertise in electronic manufacturing is highly important. FASA has been providing total automation solutions to electronics manufacturers for years such as material handling, assembly, testing and vision inspection.

We make customized micro precision automated equipment, high volume wafer-level packaging systems & complex multi-function automation systems for the production of proprietary components by global leaders in Microelectronics. We have developed new methods to produce devices that consume less energy. We build system that are flexible and adaptable to keep up with constantly evolving electronics demand. Our qualified, highly talented, experienced, and dedicated engineers with the support of our trusted vendors will provide you the best possible solutions for your manufacturing needs & challenges.

OPTICAL Bar Alignment and Stacking MACHINE

A high precision system designed to reconstruct the Optical Bars on a Glass Jig, incorporates an advanced vision System to facilitate the alignment, reconstruction and measurement of the final product.

Product: Optical Bars/Prism Bar

Handling: Auto Loader/Unloader, Pick and Place, XYT Active Aligner.

Function: Alignment, Stacking, Measurement of the Optical Bars on a Glass Jig.

Optical Bar Sorting and Binning Machine

Uses an advanced Vision Inspection system to ensure precise inspection the Y Pitch, Surface and Thickness of the Optical Bars, sort and load them to their designated Bins.

Product: Optical Bars/Prism Bar

Handling: Tray Load to Bin Unloading, Auto Pick and Place.

Function: Y-Pitch sorting, Surface Inspection, Thickness Check, Binning

WLO Attach Machine

A high precision system designed to attach a side wafer to optical bars and UV Curing for proper bonding.

Product: Optical Bars/Prism Bar and Side Wafer

Handling: Input Conveyor, Auto Pick & Place, Carrier, Stacker.

Function: Epoxy Vision Inspection, Stacking, Alignment, UV Curing.

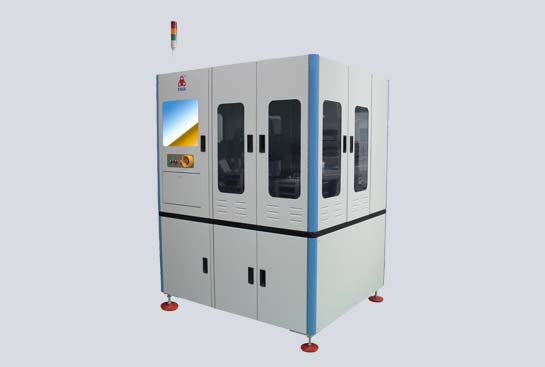

WLO Laser Marking System

A high precision system that utilizes a highly reliable & stable laser system to perform 2D Barcode Laser Marking on WLO. Performs Highly accurate vision alignment and pre-laser marking & inspection procedure before large area marking to ensures a high-quality laser marking result.

Product: Wafer Level Optics (WLO)

Handling: X, Y, Z & Theta Axes movable, Vision Assisted Alignment, SCARA Robot for Wafer Handling, Wafer size: 6”-8”.

Function: 2D Barcode Laser Marking, Vision Inspection.

WLO INJECTION COATING MACHINE

Automate the process of coating WLO units with epoxy. The epoxy is injected into a glass mold that encloses the product and then transported to a high-quality LED UV lamp for UV curing

Product: Wafer Level Optics

Handling: Carrier, Lifter

Function: Linear Dispensing, Epoxy Injection, Vision Inspection, UV Curing, IPA Cleaning.

WLO Stacking Machine

Performs high precision and accurate stacking process of Wafers. This system performs high precision vision alignment and UV Curing process for precise bonding of wafers.

Product: Wafer Level Optics (WLO), Wafer size: 8 inches

Handling: Top & bottom Chuck, X, Y, Z & Theta Axes, Alignment accuracy: ± 3mm

Function: Wafer Stacking, UV Curing

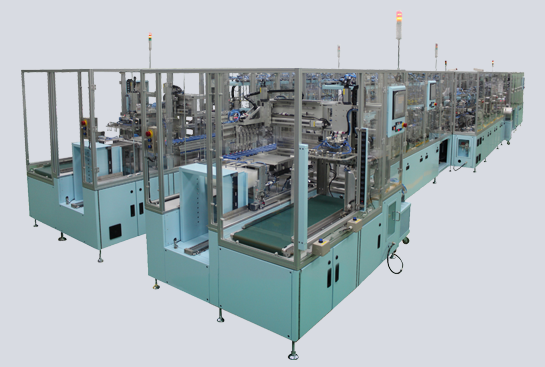

Smart Phone Battery Manufacturing line

High-speed and high-precision system designed to automate the wing folding process of Lithium Battery Cells used in various devices, including the latest generation of smart phones, tablets and devices.

Product: Lithium Battery

Handling: Tray Loader/Unloader, Auto Pick and Place, Conveyor System, Transfer Station, Hot/Cold Press, Flipper, Centering

Function: Auto Loading, Forming (wing fold), Hot & Cold Press, Vision Inspection, Leak Test, Impedance Check, Thickness Check, Dimension Check and Auto Unloading, Laser Marking.

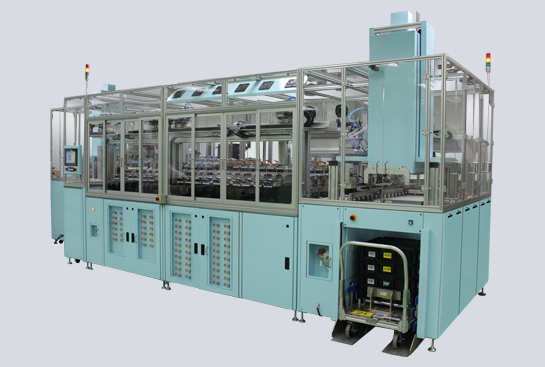

Lithium battery Shipping Press Machine

Fully automatic high-speed system designed to perform Hot and Cold press of Lithium Battery Cells.

Product: Lithium Battery

Handling: Tray Loader/Unloader, Auto Pick and Place, Conveyor System, Tray Transfer System.

Function: Hot Hold, Cold Hold, Sorting, Barcode Print and Place.

Lithium Battery Hi-Pot Testing Machine

Performs punching and Hi-Pot testing of Battery cells.

Product: Lithium Battery

Handling: Pick and Place, Conveyor

Function: Cell Punch, Hi Pot Testing, Sorting.

For more information or request brochure on our products or services, please contact us.